By Joseph Sam

A CT tube plays a major role in providing images to help diagnose disease or injury. While radiologic technologists work with them every day, they might not always think about the life of the tube in their machine and how they can help improve it. Doing so can help extend the life of the tube, provide quality imaging, and save a hospital from unexpected headaches and expenses.

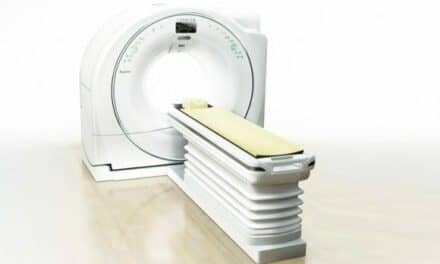

The CT tube is housed within a machine’s gantry, a circular, rotating frame where the tube is mounted on one side. As the gantry rotates, it spins the tube around the patient, creating a fan-shaped beam of x-rays that produces several thousand sectional views of the patient’s body. This data is then used to create a 3D visualization for a more detailed view of the scanned area than a typical X-ray would provide.

Depending on the model, CT tubes typically last anywhere from 350,000 to 750,000 scan seconds. During preventive maintenance (PM), engineers look at the scan-seconds data and possibly make recommendations for servicing or replacing the tube, if needed. However, imaging technicians can also learn the hard way that tube issues may arise if they don’t follow OEM guidelines.

Warm Up to Reduced Costs

Some hospitals might conduct a warm-up on their system every few days, or once per week, but it is crucial to follow the manufacturer’s recommendations on proper CT tube prep. If a machine has been sitting unused for one or two hours, the system should be warmed up before each use. At a minimum, a warm-up should be conducted every 24 hours. Using the tube without warming up can cause premature failure to occur, but this can be easily avoided.

Just as a person would stretch before playing sports, warming up the CT tube helps it function better. While some might view the recommended warmup frequency as unnecessary or an annoyance, it only takes two to three minutes and can help extend the life of the tube. Consistent warm-ups can avoid the more serious headache of scan issues and help lower unexpected replacement and service costs.

Being sure to apply the proper current, voltage, and exposure time for each individual scan and not exceeding the recommendations per machine can also help extend the CT tube’s life. Overall, following the maintenance and operation recommendations that the OEM provides is the best way to keep a CT machine running smoothly, including the tube.

Signs of Trouble

There are a variety of warning signs that might signal an issue with a CT tube. But if you take early action on these signs, the issue can be resolved before it becomes larger and more expensive.

Take arcing, for example. Often occurring during the middle of a CT scan, this happens when there is a short circuit within the tube and is documented by error messages in the log. However, when an arcing error is accompanied by an immediate shutdown, this means that arcing is happening too frequently. Such an occurance could signal an issue with the tube itself or something within the x-ray system that should be serviced as soon as possible. Fortunately, an engineer might be able to prolong the life of the tube until a replacement can be arranged.

Moreover, if there is a humming sound coming from the tube bearing, it could mean that the bearings inside the tube housing are wearing out and should be inspected by an engineer. When CT technologists notice any kind of irregular sound with their machine, they should have it investigated further by an engineer to troubleshoot the potential issue.

Also, CT systems will occasionally stop to let the tube cool down when it reaches peak operating temperature. However, if cool-downs become more frequent and longer than usual, it could signal a problem with the tube. Since cooling is essential to the life of the CT machine, any cooling-related issues should be investigated by an engineer as soon as possible.

If the machine is running without errors or other signs, but images have artifacts that affect the image quality or make it unreadable, the tube likely needs to be serviced or replaced. Not being able to read a scan can lead to rescheduled scan appointments and further downtime.

If any of these warning signs are present, an imaging engineer should be called for service. If caught early enough, the issue can potentially be kept to a minimum before too much damage occurs to the tube. And if the issue is too severe, an engineer may be able to run measures that keep the existing tube running while a replacement tube is arranged.

The Cost of Neglect

If you’re driving a car with squeaky brakes, you might not have them checked as long as the brakes keep working. Later, when you finally do take the car in to get checked, the brake pads might be diminished to the point where the problem has extended beyond the pads, requiring you to purchase expensive new rotors on top of new brake pads.

Similarly, if a CT machine is experiencing minor warning signs that go untreated, these annoyances can become much bigger headaches. Taking proper care of a machine can not only help extend the life of a CT tube; it can also help avoid issues from developing into larger problems and causing unnecessary downtime and high service-related costs.

For example, if a machine is down for 24 hours, and there were 24 missed scans in that time period, based on an average scan price of $1,700, that’s $40,800 in lost revenue. The financial impact of system downtime can also extend beyond the time you wait for a device to get repaired. A patient might need to visit another provider if their scan appointment gets cancelled, and they might choose to continue seeing that other provider going forward since that’s where their scan was conducted.

If a tube needs to be replaced, its price will be prorated based on the number of scan-seconds the tube has. And while replacement tubes can be costly, they are much less expensive than replacing an entire CT machine. Fortunately, proper care and maintenance of a machine can help avoid that ultimate replacement cost.

Replace with Value

If a replacement tube is needed for a CT machine, it’s important to make sure that the right part will arrive in working condition. People might assume that only OEMs provide brand new replacement parts, yet both OEMs and other suppliers work with both used and new parts. It’s worth spending some time to find the right vendor.

CT tubes are one of the most costly parts on a machine, but the purchase of this part is about more than just price. Since time is money, be sure to work with a trusted vendor that has a solid reputation for minimizing downtime, has expert parts sourcing and analysis, provides 24/7 technical support, and takes proper care in how they ship their parts.

While scan seconds and cost on replacement tubes is important, they are not the only variables to consider. Service, reliability, and quality can help extend the life of a replacement tube, so the replacement process doesn’t have to be repeated in the near future. Whether maintaining the life of a current CT tube, or looking at options for a replacement, investing a little time in the process can end up saving unnecessary costs and headaches going forward.

Joseph Sam is an imaging support engineer at Technical Prospects. Questions and comments can be directed to 24×7 Magazine chief editor Keri Forsythe-Stephens at [email protected].