Biomedical and clinical engineering departments are no longer just “fix-it” shops (if indeed they ever were). In many institutions, they have become partners in enterprisewide initiatives that seek to improve the quality of patient care while at the same time lowering costs—or presenting smarter economic choices.

Clinical engineering departments are often expanding their capabilities and services, offering equipment expertise in the form of data and opinion on capital acquisitions, planning (financial and physical), training and use, and, of course, maintenance and repair. Biomeds are completely cross-departmental, working with clinicians, information technology teams, construction professionals, administrators, and, occasionally, even patients.

When possible and cost-effective, clinical engineering departments have assumed more responsibility—from taking on new roles to new equipment. Many teams have incorporated radiology inventories into their service capabilities, saving the larger health care institution money through less expensive service as well as greater uptime. Some clinical engineering departments are even taking on linear accelerators, along with other high-end radiological devices.

With most of the hospital covered, a natural next step would seem to be the clinical laboratory, where high-end analyzers get high-volume use. However, biomeds are rarely involved, and the evolution into assuming even a first look at these devices has been slow.

This is in part because of reagent rental agreements—where the laboratory agrees to purchase all reagent from the OEM and the OEM provides service for “free”—and because the numbers have not made much sense. Too much variety, too little inventory—the cost of extensive training may not be worth it for one system, particularly if reliability is high and technician exposure is low. However, biomeds are making some inroads.

Some facilities’ laboratories are working with clinical engineering on capital acquisitions that make smarter life cycle investments and, as a result, are moving away from more traditional reagent rental agreements. Greater collaboration brings greater trust, and biomeds find they are also making progress in laboratory relationships. Some clinical engineering teams are even assuming responsibility on analyzers traditionally out of their realm, even if it is solely management of service contracts.

“I believe that the clinical lab is the next frontier for clinical engineering to conquer, but it will take a lot of work to accomplish this,” says John R. Short, Midwest field service manager for TriMedx Healthcare Equipment Services, headquartered in Indianapolis. Much of that work, according to Short, will include education about the advantages—at all levels, from laboratory manager to the chief financial officer (CFO). When the numbers are right, people will listen. “The increasing need for cost savings will be the main driving factor behind this transition,” Short says.

Some facilities’ laboratories are working with clinical engineering on capital acquisitions that make smarter life cycle investments and, as a result, are moving away from more traditional reagent rental agreements.

A NATURAL EVOLUTION

“The more we get involved with laboratory equipment, the more value we can provide, in part, because we have a faster response,” says Nidal Alammari, manager of clinical engineering at the Ronald Reagan UCLA Medical Center, part of the UCLA Health System, Westwood, Calif. As discovered in radiology, having a trained expert on-site can increase uptime, which is critical to the lab.

But this expertise does not come free. “In order for the clinical engineer to be successful, the lab needs to negotiate biomed training and parts-only contracts before the purchase of equipment,” Short says. “Once the equipment has been purchased, it is very hard, if not impossible, to get the OEM to agree to these conditions.”

Involving clinical/biomedical engineering at the acquisitions stage can help ensure that smart decisions are made and service is properly maintained, in addition to negotiating for training and parts. “[The laboratory and administrators] see the value in it because we have the dedication to answer a lot of questions, to find out if equipment is going to become obsolete in upcoming years, and to determine whether a multiyear service contract is suitable for cost,” Alammari says. “There are a lot of things we bring to the table that may not have been done before.”

Continued involvement past the acquisition stage can also translate into continued value. “It’s good to have a handle on the equipment in laboratories,” Alammari says. “We look at it as a whole, considering their service needs. We want to make sure we have what’s needed, that equipment is being maintained on time so it is working when it is supposed to be working, and that we lower the cost of maintaining equipment where possible.”

Evidence of cost savings can tip the scales. According to Short, if the CFOs and lab managers see the cost savings that the clinical engineers can bring to the lab, buy-in for in-house service typically follows. “Some labs have seen the advantages of purchasing the equipment and looking at options for servicing the equipment,” he says. “The labs with the most options for service are the labs that purchase the equipment and negotiate training for their biomeds with that purchase.”

COMPLICATED AND VARIED

Clinical laboratories with existing equipment and service contracts may not find biomed involvement cost-effective until new instrumentation is brought in, but even then it can sometimes still be challenging to justify the time and expense. There are many more modalities used in the lab, and those that are used require less service when compared to devices in radiology, according to Alammari. The laboratories themselves are diverse and can include blood bank, chemistry, coagulation, cytology, hematology, histology, microbiology, and pathology.

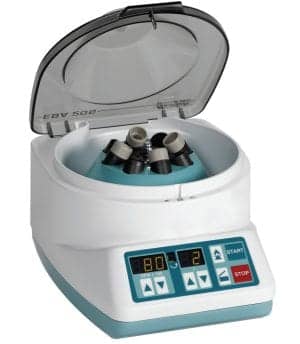

Smaller devices that are key to lab operations include centrifuges (pictured), spinners, and refrigerators.

“In a laboratory environment, the clinical engineer might not get interaction with the equipment for sometimes 2 to 3 months,” Alammari says. It, therefore, becomes difficult to train a biomed to the degree necessary to be cost-effective.

At the same time, the laboratory workload can be quite heavy. In addition to high-end analyzers, there are a significant number of smaller devices that are also key to operations, such as centrifuges, spinners, and refrigerators. Alammari has two biomeds who specialize in laboratory devices, one dedicated full time and the second about 60%.

At TriMedx, there are clinical engineers dedicated to the various lab specialties. “The workload for the lab engineer is stressful and includes a lot of after-hours calls. It’s not unusual for a lab engineer to receive a hematology or chemistry call at 2 or 3 in the morning,” Short says.

Additionally, high-end analyzers are complicated pieces of equipment that can require an extensive amount of technician time. A simple PM can take 8 hours, and troubleshooting an intermittent problem can be problematic. Integrated equipment (a trend in laboratory development) has many components, and an isolated problem can be time-consuming to find.

“A lot of times with lab equipment, the hardware can be working fine and the chemistry’s the problem. We would get called in many times and spend 6 hours troubleshooting to find the lab had been pooling reagent,” says Jeremy Compton, CBET, biomedical services at Winona Health, in Winona, Minn, referring to a previous position as a field service technician. (Pooling reagent is a cost-saving move implemented by laboratories where old reagent is combined with new to avoid throwing any away.)

Biomeds can also be challenged to stay up-to-date with more complicated machinery. “Manufacturers often change their assays and upload other improvements,” Compton says.

In addition, OEMs can charge high fees for parts. “Some manufacturers have raised the price of their parts to keep clinical engineers from being able to service their analyzers,” Short says, adding that parts-only contracts are therefore key negotiating points.

GETTING THERE

As more laboratories veer away from reagent rental agreements toward the purchasing of capital equipment, negotiations are more complex. Many laboratories and facility administrators have become aware of the importance of considering all aspects of a contract in terms of a piece of equipment’s life cycle; upfront acquisition cost is no longer the only, or even the biggest, concern. And though reagent rental agreements are still commonplace, they can be expected to become less so as facilities update instrumentation.

At Winona Health, a community-owned, nonprofit organization, reagent rental agreements still predominate, Compton notes; at UCLA, new high-end analyzers are purchased rather than acquired under reagent rental or other service agreements, Alammari says. The clinical engineering team does not service the high-end analyzers, but it does manage the service contracts, a transition that happened about a year ago. Prior to that, the laboratories managed these aspects directly.

“It was a good change for us,” Alammari says, citing the ability to ensure that the equipment works well and works safely. “Our part, policy-wise, is to ensure the safety of the equipment, the user, and the patient, and to make sure it is maintained within the guidelines of The Joint Commission as well as federal and state regulations.”

The two team members who work with laboratory equipment at Ronald Reagan Medical Center have significant experience in the area. “There is great value in having really experienced staff who can make sure we are able to maintain the service level we need to provide for the lab,” Alammari says, noting they can also back one another up.

Clinical engineers providing service to lab equipment should understand what the equipment does and how it operates. “The results from the analyzers are what the doctors use to diagnose their patients, so it is critical for the equipment to be working correctly,” Short says. “Biomeds that work on lab equipment need to have a thorough understanding of how the equipment is used.”

It can be challenging to understand how each piece of equipment works, particularly when there can be multiple kinds that operate slightly differently. “In the past, when HPLC—high-performance liquid chromatography—was the main equipment, we had to understand how it counted cells, but it was different with every piece, which is why it’s a little harder than radiology,” Compton says.

Clinical laboratories often run 24/7 and, like radiology, are key to patient diagnosis. Downtime cannot be tolerated; an inability to get answers can negatively impact patient care and the bottom line. With clinical engineering departments thriving on missions to improve care and lower cost, it is likely more will assume greater responsibility within the clinical laboratories, as they have in radiology, to the benefit of all. Clinical labs are not likely to be the final frontier for biomeds, but they certainly seem to be the next.

Renee Diiulio is a contributing writer for 24×7. For more information, contact .