A new report highlights quality control gaps and potential safety hazards from non-OEM 18650 cells, which are used in some medical devices.

A new report from industrial CT scanning company Lumafield reveals a significant quality and safety gap between brand-name and low-cost 18650 lithium-ion batteries, a cell type used in devices ranging from consumer electronics to medical equipment. The research found that nearly 8% of low-cost or counterfeit batteries could have a dangerous manufacturing defect known as negative anode overhang.

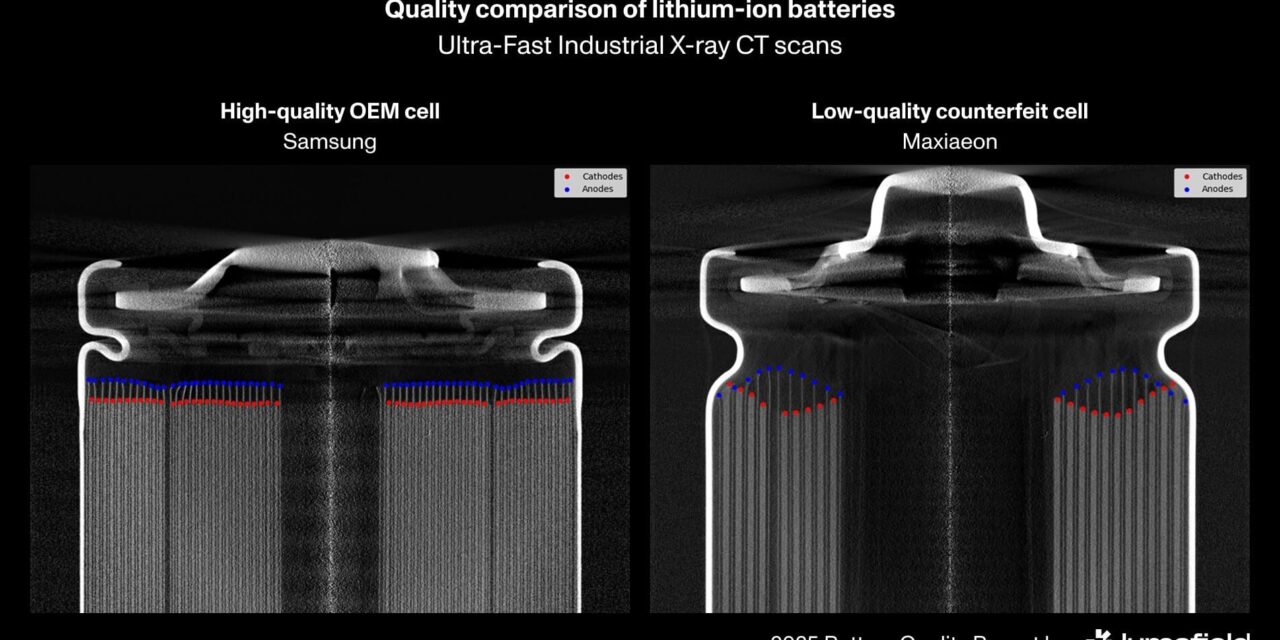

The 18650 form factor is a common power source for portable electronics. However, the study indicates that quality varies widely between original equipment manufacturer (OEM) cells and the low-cost or counterfeit cells available through online marketplaces. According to the report, key indicators of quality in low-end batteries are seven times worse compared to those from name-brand manufacturers.

These defects can impede the performance of the devices they power or, in some cases, increase the risk of catastrophic fires. The Consumer Product Safety Commission issued 26 recalls and nine product safety warnings in 2024 related to fire and burn hazards from battery overheating.

Implications for Supply Chain Management

To conduct the study, Lumafield used industrial X-ray CT scanning on a sample of more than 1,000 cells from 10 different brands. The results showed clear, measurable indicators of risk in non-OEM cells, highlighting the importance of supply chain verification for organizations that procure and service battery-powered devices.

“Non-OEM batteries are a minefield,” says Eduardo Torrealba, co-founder and CEO of Lumafield, in a release. “We’re seeing dangerous defects at a scale that should alarm every manufacturing leader. If you’re not policing your supply chain, you’re gambling with your brand and your customers’ safety.”

Key findings showed:

- Of the 1,054 battery cells scanned, 33 had negative anode overhang, a manufacturing defect that accelerates aging and significantly increases the risk of internal short-circuiting and battery fires.

- All 33 of the defective cells came from low-cost or counterfeit brands, meaning one in 13 (nearly 8%) low-cost/counterfeit batteries could have this dangerous defect.

- One low-cost brand acquired through Temu had a 15% rate of negative anode overhang defects—a serious risk to consumers who may be tempted to acquire inexpensive batteries through the marketplace.

- On other measures of cell quality, low-cost/counterfeit batteries are seven times worse than their OEM counterparts.

- Low-cost/counterfeit 18650 cells had 50% worse edge alignment—referring to the winding of the internal layers of the cylindrical battery—compared to OEM cells. This represents yet another quality concern that can cause performance degradation and internal short circuits.

- None of the 300 brand-name OEM cells from Murata, Samsung and Panasonic had negative anode overhang, suggesting that batteries from these high-quality manufacturers sourced through legitimate retail channels are the safest and most reliable cells.

- The risks in individual cells are compounded by the fact that many products include multiple 18650 cells—from five in a typical cordless drill to 39 in an e-bike battery pack that Lumafield CT scanned for the study.

The report emphasizes that while industrial X-ray CT has historically been a slow and expensive tool for quality verification, newer technology allows for faster inspection.

“Many of us have become desensitized to warnings about the dangers of lithium-ion batteries, but our research underscores why consumers must be vigilant,” says Alex Hao, author of the Lumafield Battery Quality Report, in a release. “It can be inconvenient to properly use, store, and dispose of batteries, but there’s no room for complacency. Furthermore, consumers should be mindful of where they buy their batteries. If a deal looks too good to be true, it probably is.”

Photo caption: Industrial X-ray CT scans illustrate the quality gap between an authentic OEM lithium-ion battery (left) and a low-cost counterfeit (right). The OEM battery exhibits excellent quality control, with tightly aligned layer edges and even anode-cathode overhang. The low-cost battery has highly variable anode-cathode overhang and a dangerous defect called negative anode overhang. Captured with a Lumafield CT scanner and analyzed with Lumafield’s Battery Analysis Module.

Photo credit: Lumafield