George Hryshchuk is the director of sales for Advanced Ultrasound Electronics (AUE), a company in Tulsa, Okla, that repairs and sells ultrasound parts. Fifteen years ago, when he was directing training at Denny’s restaurants, he wouldn’t have guessed that ultrasound was in his future. But when his brother John founded the company in 2001, George came aboard, doing everything from answering phones to repairing equipment to tracking company finances. Now the two brothers, along with another brother, Greg, all work together and continue to grow the business—they are looking to double the size of their shop space in the near future. 24×7 sat down with George and discussed how the business has grown so quickly, and how they balance competitiveness with helpfulness.

24×7: When was Advanced Ultrasound Electronics founded, and what was the differentiator that set you apart from similar companies?

Hryshchuk: We were founded in 2001 as an exclusive ultrasound repair company. At that time, we were one of the first companies to do the repairs and then run tests for physical functionality on an actual system. That’s different from sending the board to an electronics repair place; they can’t put that particular board under a load. They can run it and test it, but they can’t put an actual load on it as a machine would do.

|

A Quick Take

24×7: How did you get started in this line of work? Hryshchuk: I had been with Denny’s since 1983—I started as a busboy and worked my way up to area training manager for a Denny’s restaurant franchise. When my brother John founded AUE in 2001, he gave me the opportunity to start working with him. (Greg, another brother, came along in 2006. He works with office management and accounts payable and receivable.) I started by answering phones, setting up our accounts payable and receivable. I set up our database. From there I went on to help doing some of the repairs as a repair technician. |

24×7: What’s the benefit to the customer?

Hryshchuk: How do you know if your board is working properly? You can put the board under regular diagnostics and it passes, but some probes put a heavier load on the power supply, which can cause parts to pop or capacitors to blow, or you’ll get noise on the screen, or you’ll get double image, or the probe won’t ID. We find these things out from QA and through the customers.

24×7: Why weren’t more companies doing that?

Hryshchuk: Not everyone wants to invest in systems for every board. That’s what set us apart from other companies. Now, there are other companies that do similar work—others now have actual test beds—but we were one of the first companies to do this test on the component level and put the boards under an actual load.

24×7: How have the company’s offerings grown and changed since those early days?

Hryshchuk: We started doing exchanges on boards and probes. Then we added peripherals sales and repair—VCRs, printers. We’ve actually backed off offering some of the peripherals because everything is going digital now. We now do everything from system service, sales, board repairs and exchanges, and probes. We do minor probe repair, but we really don’t do full probe repair—we’re not set up for that.

24×7: What areas of the country do you service?

Hryshchuk: We do service up to 8 hours outside of Tulsa. We also have a foothold in Dallas. We can reach Arkansas and Kansas. We are just starting service in the Southwest. We added a regional salesperson in Phoenix. He’ll work with people in Arizona, New Mexico, and Nevada.

Our original building was 3,000 square feet with 750 square feet of shop. We grew to 6,000 square feet and then moved to a 9,000-square-foot building. Now we are looking to double in size to about 20,000 square feet or more, to accommodate the growth. We’re going to bring more people on for infrastructure and repairs. We ship and receive 600 to 800 shipments per month. We currently have about 15 people working at AUE.

24×7: What are you doing to stay ahead of the curve and ahead of the field?

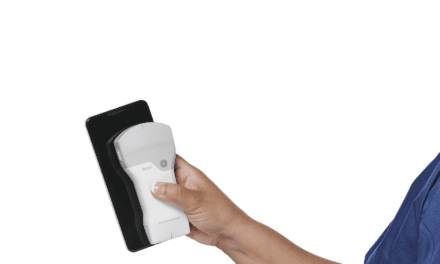

Hryshchuk: It’s important to stay up to date with the newer systems: the Vivid and Logiq E9s; back-end processors; all of the new Philips equipment, including the CX50 portables.

As far as other companies, we work together and compete against each other. It’s like a family. We can’t have every part every time, so we try to work together. When other dealers ask me for parts and I don’t have it, I don’t quote it—I try to send them to someone who does.

24×7: When considering a service contract, what would you recommend people pay extra attention to?

Hryshchuk: Availability of parts. When your system breaks down, how easy would it be to get a part for that system? Even if it’s under warranty, you might not get a part for a while—then your system is going to be down either way. One advantage we provide to people who buy systems from us is that we offer loaner systems.

In the end, I believe it’s a combination of having the parts available, getting it to the customer by the next day, providing quality technical support, and, of course, offering all that for a fair price. 24×7

Kurt Woock is the associate editor of 24×7. Contact him at [email protected].