?Since its invention in 1913, the x-ray tube has evolved into a unique piece of equipment. The technology is extremely versatile, with applications ranging from travel security to medical diagnosis. When your baggage goes through airport security screening, an x-ray tube is used to provide images of items that are unseen to the naked eye. It allows security personnel to see inside the contents of luggage.

The same technology is used for medical purposes, like diagnosing an illness or seeing the extent of an injury. Depending on its intended application, an x-ray tube will have specific differences. The fundamental technology, however, is the same whatever the application.

At Dunlee, a division of Philips Healthcare, x-ray tubes are manufactured for use in computed tomography (CT) medical applications. Often, the systems that these products go on are extremely complex. Engineers who work on these systems must install the x-ray tube according to the exact specifications outlined in the OEM manual. It is not uncommon for issues to arise during this detailed process. This is where I come in, as an engineering technical support specialist for the field.

How X-Ray Tubes Work

Before discussing ways to improve tube life, it is important to understand how x-ray tubes function.

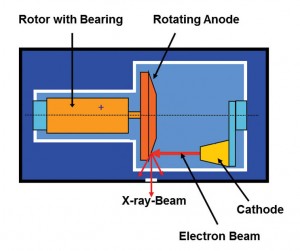

X-rays are created by bombarding a material with a high-speed electron beam. The heavier the material, the more productive this process is. Typically, tungsten is used as target (anode) material, since it is so heavy.

It is interesting to note that this process is incredibly inefficient. Of all the energy put into the tube to create the x-ray beam, only 0.5% becomes x-radiation. The remaining 95.5% is mostly heat. The more x-radiation you create, the more heat must be absorbed by the tube.

X-rays are invisible to the human eye and are able to pass through most materials, with some loss of energy. This energy loss splits the atoms and releases electrons from the material. This release is called ionization or x-radiation. A heat exchanger and pump are used to avoid overheating the CT tube. One can think of the heat exchanger and pump as being very similar to a radiator in a car.

Every x-ray tube has a glass or metal insert under a vacuum. The insert is placed in a lead-lined shell, and oil is used to keep the insert cool. Hot and cold oil is circulated to keep the tube from overheating.

The anode or target of the x-ray tube can spin from 3,500 to 10,000 RPM, depending on the use and manufacturer. The heating and cooling cycle can be a detriment or a savior for the tube. It is this process that puts stress on the materials, like tungsten, molybdenum, and zirconium, that the x-ray tube is built on. Typically, the more a tube is used with reduced cycling of heating and cooling, the longer the tube lasts.

The most common failures for a tube are arcing, frozen rotor/anode, and filament evaporation. These are all considered normal end-of-life failures.

Maintenance

Now that you know how a tube works, let’s discuss how to keep this sensitive engine humming for a long time. Tubes need TLC! Just as when you take care of your car, doing regular preventative maintenance (PM) of CT x-ray tubes will keep them running longer. The two major factors to extending tube life are how it is used and how often PMs are done. Proper PMs will keep you aware of any changes and will aid in extending long life for your tube and the system it is installed on.

CT PMs do not come in one size fits all. With the advent of technology and software, many manufacturers may suggest twice-a-year or quarterly PMs.

In the mid-1980s, monthly maintenance was the norm. During this time, there was a room separated with air conditioning and 10 to 15 or more microprocessors running a huge back projection section, and numerous gates and transistors, among other things. Back then, when you had a problem, you could run to the local Radio Shack, grab a NAND gate, and the system would be up in less than an hour!

It was also common to see switching tanks, tetrodes, diode sticks, and rotor controllers. Changes in technology in the years since have made these systems simpler and faster. However, mechanical parts tend to wear out sooner, since the centrifugal force is many times greater than in the mid-1980s.

This brings us to the basics of what is best for each end user. For example, for an end user facility that runs 50 patients a day, it is recommended to do monthly PMs with a two-fold focus: one on customer issues and another on system issues.

Whether you are a third-party service provider or an end user at a hospital, it is crucial to have a close relationship with your customer or radiology department. In order to properly take care of a system, you must know how it is used. More often than not, end users are so busy that they do not have time to tell you about an incident with the system or a noise in the table or gantry. Therefore, it is important to know the site well and take time to learn about any possible issues. Having a close relationship with end users is a huge help to keep the system running at peak efficiency.

The final piece of advice I will leave you with is this: Take care of your equipment (both the CT system and the tube), and it will take care of you for a long and prosperous life! 24×7

Phil Bogolub is a technical support engineer for the Dunlee division of Philips Healthcare, Aurora, Ill. For more information, contact 24×7 editorial director John Bethune at [email protected].