For healthcare technology management (HTM) professionals, biomedical test equipment is key to getting the job done Four individuals with a vested stake in the test equipment market—Greg Alkire, vice president of sales and marketing at Pronk Technologies; Tim Welby, national sales and marketing manager at BC Group; Michael Raiche, senior product manager at Fluke Biomedical; and Michael James Walton, MSc, category medical at Rigel Medical—sit down with 24×7 to share their insider information.

24×7 Magazine: How has the pandemic impacted the sector?

Michael Walton: COVID-19 has been a huge challenge in a multitude of different areas. We all know many people across the globe have tragically lost their lives from this deadly virus. Our customers, unfortunately, had a front row seat of these events unfolding before their eyes, fighting on the front line when no one really knew or had any experience or knowledge of how long this horrific disease would last.

The demand for test equipment quickly shifted toward COVID-19-related test tools, ventilation, electrical safety analyzers, etc. Biomedical engineers also contended with an increased demand on capacity and had to find ways to mitigate risks—putting provisions in place to prioritize the maintenance of life-saving equipment.

Greg Alkire: The pandemic has caused supply chain challenges in our industry, creating delays in production and shipment of orders as compared with pre-pandemic time frames. At Pronk, we took very aggressive steps to manage inventory levels and work with key suppliers to minimize any disruptions with parts needed to manufacture our products. During this difficult time, we wanted to ensure we could continue to maintain our commitment to the HTM community, delivering quality products when they needed it most.

Tim Welby: With HTM as an essential business, the pandemic had a major effect as the needs shifted to very specific testing equipment—i.e., respirator testing and meeting the volume demands. We were like chameleons, changing on the fly to meet customer and patient needs.

Michael Raiche: At Fluke Biomedical, we saw the impact from the pandemic in the rapid and heavy increase in demand for medical devices and the subsequent need to test them. Patients required hospitalization and intensive care treatment. The world needed to test emergency department and intensive care unit medical devices—not just ventilators, but also patient monitors and infusion devices.

Demand also spiked for new medical devices, and manufacturers responded by bringing new capacity online, including suppliers new to medical device assembly and testing. We’re proud that we had the right test instruments, at the right time, and could teach the proper use of our test equipment to navigate the pandemic from production line into the hospital.

24×7: What are some of the top trends in the biomedical test equipment sector right now? What do you anticipate will be the “latest and greatest” in test equipment in the next few years?

Raiche: We see medical device cybersecurity as a top trend as medical devices continue to become more connected. Another top trend in that same vein is the Internet of Things, whereby software and hardware became increasingly integrated. A third top trend we see is biomedical departments using new technologies to streamline workflows and further their ability to do predictive maintenance.

Fluke Biomedical sees the “latest and greatest” in biomedical test equipment as software-enabled quality assurance (QA) and preventive maintenance tools that can securely and seamlessly integrate into these modern workflows. That is why we are investing in our OneQA software and its ability to integrate, not just our own test tools, but with other software programs. We are working with industry partners such as Nuvolo, Accruent, and Ultimo so customers can use our Fluke Biomedical OneQA software to integrate our test tools into their connected workflows.

Welby: Bluetooth capabilities to increase productivity and reduce transcription errors. Auto sequencing has been around, but BC Group is looking to expand the offering to additional pieces of equipment. We continue to talk with the customer to determine their needs and what’s important to them.

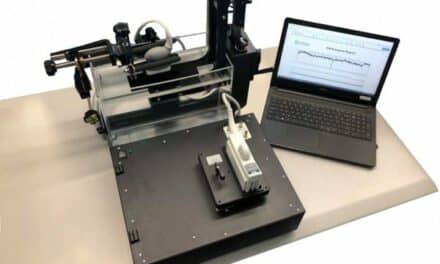

Alkire: Pronk introduced the Mobilize wireless solution to provide clinical engineers with the ability to complete their service work in a highly effective, efficient way. Mobilize delivers the capability to control our test equipment wirelessly and execute user-defined or preloaded testing protocols direct from their smart device via our Mobilize app. Mobilize will automatically transmit the required tests to the test equipment, report back the results, and generate a complete electronic test report that captures tests performed, test results, device and facility information, images taken, and test equipment used, including the respective calibration dates.

Mobilize also provides the capability to create and print a PM sticker from a wireless label maker. This enables a clinical engineer to perform all the service required completely paperless. Mobilize also has a wide range of methods to transfer the information to a CMMS/database.

Walton: Biomedical engineering requirements for test tools outside of generic test and measurement is a niche area. Electrical safety is common to all electrical medical devices so naturally there is more demand in this area. Has the improvement in technology of medical equipment watered down the need for electrical safety? No. Do airplane technicians stop testing planes because planes aren’t falling out of the skies? No. Mitigation of risk and patient safety is our primary objective, and that is what Rigel Medical is passionate to deliver.

Technologies and innovations move on, and we’re seeing more enquires to test wearable devices. This will increase as they become more clinically accepted, and we as manufacturers need to invent novel ways to meet these new demands. This is an exciting area of potential exploration and development.

24×7: Before purchasing test equipment, what should hospitals know? Are there any potential red flags they should avoid?

Raiche: As mentioned in the previous question, hospitals should know if their biomedical test equipment will integrate into connected workflows. You don’t want to make a new equipment investment and find it lacks the capability to deliver against your organization’s technological roadmap.

Hospitals should also know if their biomedical test equipment meets quality standards. If you are testing a medical device that has undergone stringent testing before gaining market clearance, shouldn’t you expect the same of your test equipment? Ask if your test equipment is [Underwriters Laboratories]-listed, has a European CE mark, conforms to [standards imposed by the International Organization for Standardization], etc. You want a manufacturer that puts that effort into their test equipment.

A shorter-term concern is the ability for a manufacturer to ship your new test equipment. Ask questions around projected lead time to ensure you are not waiting months for your equipment. The team at Fluke Biomedical, for instance, has worked hard to ensure our supply chains are strong so that we can deliver test equipment and software to our customers in their times of need.

Welby: The cost of acquisition versus cost of ownership. As your needs change, is there an upgrade path without having to purchase a new piece of equipment?

Walton: Biomeds are metrologists who use medical equipment to measure things. Understanding specification is key to choosing the correct test tool. Manufacturers recommend test tools, which, of course, should be understood. But if a medical equipment manufacturer is brand-specific toward a test instrument in a service manual, biomeds should be aware of the underlying ‘or equivalent’ message.

Many Rigel Medical instruments are, indeed, in service manuals, but as a metrologist myself, I believe in freedom of choice and to determine the requirements of the equipment under test to decide what the best options are. Evaluate; look at alternatives; demo equipment. That is the fun part of the job.

Alkire: Like all consumers, healthcare professionals want to ensure high value for their purchases and maintain a low cost of ownership. The pandemic spiked their workload and, subsequently, their use of biomedical test equipment. In some cases, this demand resulted in higher rates of repair and service of the test equipment. This crisis has revealed the benefits of thoughtful purchases of test equipment products with a low cost of ownership. Pronk products, for example, include as standard a U.S.-best, four-year warranty. All Pronk product designs must be able to sustain 50 drops from 3 feet and then pass performance tests within specifications. Both important features ensure a low cost of ownership for clinical engineers while also minimizing downtime of out-of-service equipment.

24×7: What are the needs of your customers, and how do your product offerings meet them?

Raiche: At the end of the day, our customers are trying to deliver compliance to the hospital to ensure that medical devices perform as they should and are safe for use by both patients and operators. We know that our customers are looking to complete their work orders in as timely a manner as possible, and we offer multiple levels of workflow automation to ensure that gets done. Our products can scale from manual/push-button testing to onboard auto-sequences to fully automated solutions using Fluke’s OneQA software.

Our customers also need to trust their equipment. We offer high-quality, robust test equipment that can meet the range and accuracy requirements of regulatory bodies and service manuals. Customers can meet their specific procedures through unit-by-unit adjustment, test profile configuration, and procedure customization—and the software-enabled capabilities of our tools make it easy to capture and share that knowledge.

Alkire: Our customers value the portability and reliability of our products, as well as their ease of use. Pronk’s BMET Pack Pro—which comes with the Safe-T Sim automated safety analyzer, SimCube NIBP, OxSim Flex SpO2, and SimSlim multi-parameter simulators, plus the FlowTrax multi-function IV pump analyzer—provides customers the ability to carry all their standard test equipment, along with accessories, in a single pack. All of this is leveraged in combination with our Mobilize wireless solution, whereby engineers can control the products from their smart devices and run their test protocols/procedures from the Mobilize app to generate a complete electronic test report.

Walton: Mobility is Rigel’s key area, but equally our instruments are well suited to work bench environments. You can fit an electrical safety analyzer, a defibrillator tester, and a patient simulator in one backpack. Primarily, our customers want to test on the go, and they don’t want a hernia carrying around heavy test equipment or making multiple trips to their vehicle.

Welby: Our customers want to be taken care of from start to finish. BC Group uses the phrase, “Your one-stop biomed shop.” We will source items for customers to reduce the number of purchase orders they have to generate and take away ‘busy time’ for them.

24×7: What else should 24×7 readers know about test equipment, in general?

Welby: Keep communicating with equipment manufacturers about your needs and develop a partnership versus a transactional relationship. This creates synergies and promotes growth for the whole industry.

Alkire: Until recently, test equipment was evaluated based on the features and capabilities the device itself could perform. Test equipment needed to evolve beyond just the device itself and provide solutions that enable it to be “smarter” and more closely connected to the work required to be performed on the medical device. This type of integration between the test equipment and the clinical engineers’ testing procedures is essential to ensure the highest level of service.

The ability to connect the test equipment directly to the CMMS work order/procedure, for example, enables organizations to have their staff work directly from their system as they perform the service. This provides a uniform method to ensure the entire clinical engineering team is completing the work required with high consistency and accuracy. It also eliminates the need for engineers to manually document the service performed into the CMMS/database.

Walton: Rigel Medical has been in the biomedical testing marketplace for quite some time, and we have established global sales channels. We can’t stand still in the marketplace and will keep developing new and exciting products in the niche world of biomedical engineering.

Raiche: As we watch the incident reports and corrective actions (manufacturer-voluntary and U.S. FDA mandates), we see alarming volumes of incidents that should have been found during periodic testing. Periodic maintenance of medical devices is still required to ensure patient and operator safety, as well as the proper performance of medical devices. It’s an important reminder that performance and safety testing workflows exist to help reduce the volume of failure incidents occurring during clinical use of the medical device.